| Introduction

SIMTRUM provide the highest standards of quality service to our customers. We are certified in both the Quality and Environmental Management systems, ISO 9001:2015 &14001:2015 respectively, attesting to the stringent practices that we hold in place to meet the demands of our clients. As a continuing effort to meet customer requirements, we has implemented IATF 16949:2016 Automotive Quality Management system and targeting to get certified in 1Q-2023.

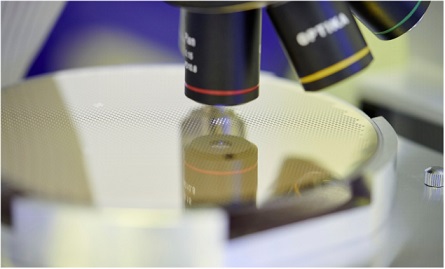

Our metrology lab consists of state of art equipment, catered to measure specifications with tight tolerances and stringent optical specifications, a key requirement for Optic and precision manufacturing. Measurements follow established ISO & ASTM standard requirements, as well as customised to customer-specific requirements. High-performance microscopes and profilometers provide high optical resolution and more accurate measurement for a variety of high-precision products. Our optical measurement solutions are in a class of their own for measuring and characterizing minuscule features with high accuracy and repeatability.

|

Product Brochure Link:  Contact us at info@simtrum.com for customized service |

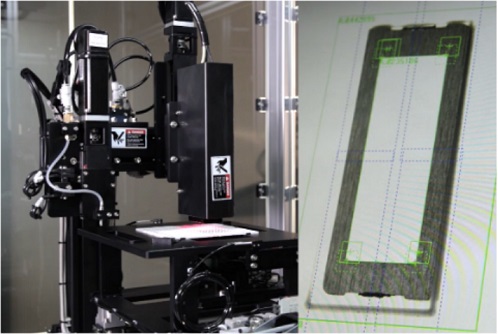

Mechanical Measurement ● OGP ZIP 250E Smartscope ● Keyence LM 1100 Optical Measurement Machine ● Motorised Force Gauge ● RCA & Linear Abrasion Testers ● Scanning Electron Microscope ● Customised Automated Visual Inspection Systems

|

Automated Visual Inspection (AOI) |

Optical Measurement

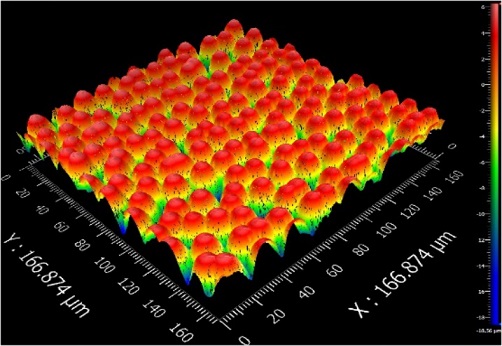

● Mitutoyo Form Tracer CS-5000 ● Taylor Hobson PGI Optics ● Melles Griot MTF / EFL Test Bench ● Zygo Verifire Laser Interferometer ● Zygo NX2 3D profiling interferometer ● Keyence 3D Surface Profiler VK-X3000 ● Luminance Meter & Light Gain Testers ● Agilent Cary 7000 UV-Vis-NIR Spectrometer ● Olympus Micro Spectrophotometer

|

Rudolph Wafer Level Inspection |

Reliability Capability

● Memmert Temperature & Humidity chamber ● Memmert Temp Cycling Chambers ● Solder Reflow Oven

Resin Control ● GoTech Melt Flow Analyser ● Radwag Moisture Analyser |

Zygo Nexview 3D Topography Analysis |

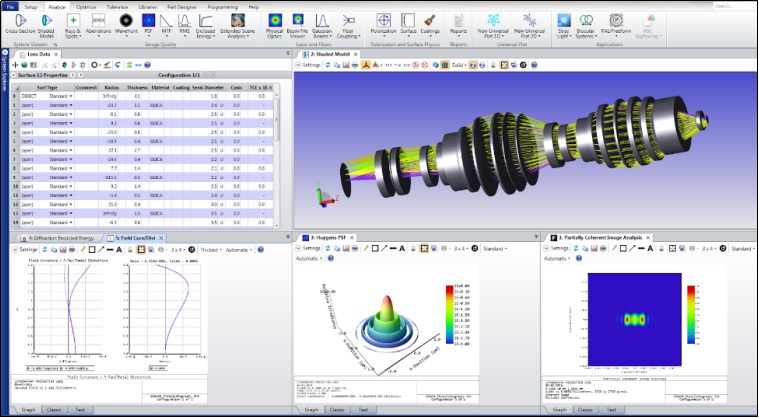

| Optical Design & Simulation Software |

|

|

|

|

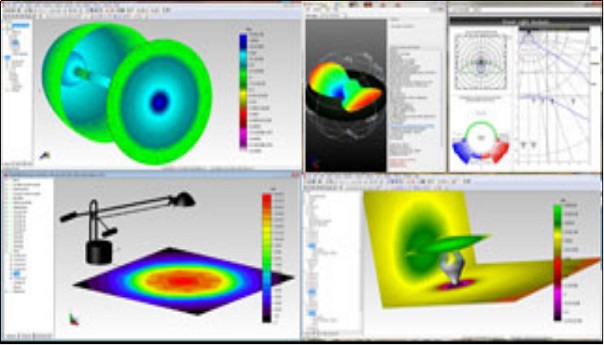

Zemax Optic Studio Refractive imagig & illumination designs & simulations |  |

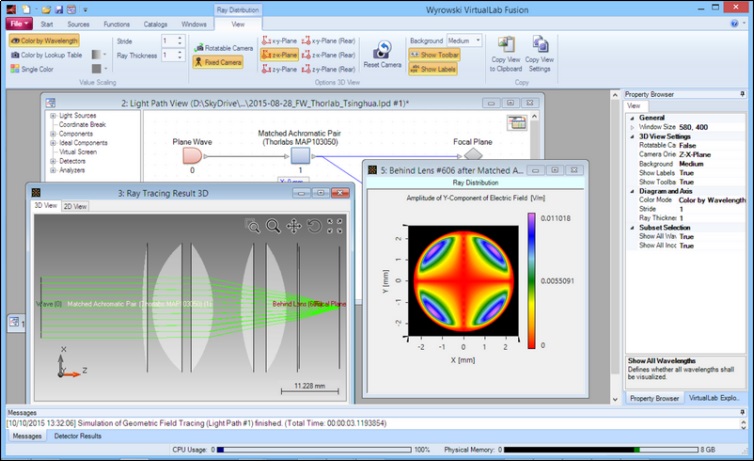

| LightTrans VirtualLab Design & optimization of diffractive beam-splitters, beam-shapers, diffusors and custom image projectors for a single wavelength light sources. |  |

|

|  |

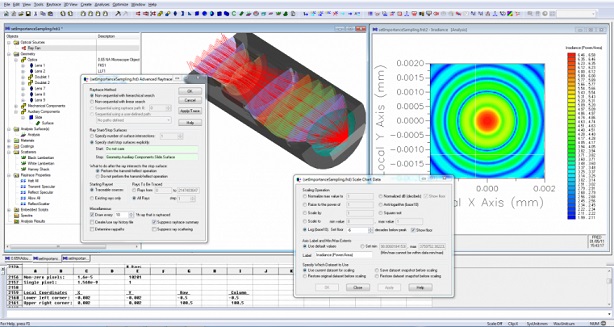

TracePro Design & optimization of diffractive beam-splitters, beam-shapers, diffusors and custom image projectors for a single wavelength light sources.

|  |

|

FRED Simulation of the propagation of light through any optomechanical system by raytracing |  |

|

|  |

| Our Equipments Memmert UF 110+ Universal Oven The universally applicable lab oven U is Memmert’s classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless-steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology. |

Features

- UF 110+ is an appliance for temperature control in quality assurance, science, research and industry. - Use for precise drying, heating, ageing, burn-in, hardening and etc. - Made of high-quality, hygienic, easy-to-clean stainless-steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology. - Temperature range from +20 to +300°C.

|  |

Technical Data

|

|

|

| Genaral Specifications |

| Working temperature range | at least 5 (UN/UNplus/UNm/UNmplus) or 10 (UF/UFplus/UFm/UFmplus) above ambient temperature to +300 °C |

| Setting accuracy temperature | up to 99.9 °C: 0.1 / from 100 °C: 0.5 |

| Setting temperature range | +20 to +300 °C |

| Temperature sensor | 1 Pt100 sensor DIN class A in 4-wire-circuit |

| ControlCOCKPIT | SingleDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display |

| Timer | Digital backwards counter with target time setting, adjustable from 1 minute to 99 days |

| Function SetpointWAIT | the process time does not start until the set temperature is reached |

| Calibration | three freely selectable temperature values |

| Adjustable parameters | temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime |

Memmert Humidity Chamber HCP105

Active humidity control creates a controlled environment for accelerated life tests and 85/85 tests. |

Features

- Active humidity control creates a controlled environment for environmental testing, environmental simulation, accelerated service life tests and 85/85 tests according to IEC 60068-2-67 and IEC 60068-2-78. - Active microprocessor control for humidifying and dehumidifying, including digital indication and auto diagnostic system ensures even more rapid reaching of set humidity and very short recovery times. - Temperature range from +18 to +90°C. - Humidity range from 20 to 95% rh.

|

|

| Technical Data |

|

| Genaral Specifications |

| Working temperature range | +7 above ambient temperature up to +90 °C |

| Setting accuracy temperature | 0.1 °C |

| Setting temperature range | +18 to +90 °C |

| Temperature sensor | 2 Pt100 sensors DIN Class A in 4-wire-circuit for mutual monitoring, taking over functions in case of an error |

| ControlCOCKPIT | TwinDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with 2 high-definition TFT-colour displays. |

| Timer | Digital backwards counter with target time setting, adjustable from 1 minute to 99 days |

| Function SetpointWAIT | the process time does not start until the set temperature is reached |

| Calibration | three freely selectable values each, temperature and humidity |

Memmert Environmental test chambers CTC256

Memmert environmental test chambers guarantee the perfect atmosphere for climate and temperature tests. |

Features

- Rapid, precise and energy-saving temperature changes makes CTC with humidity unit a perfect duo for controlled material testing, function tests, ageing tests or climate tests on composites, concrete, plastics or electronic components in material technology, the automotive and aerospace industries, and electronics. - Simulates the perfect atmosphere according to standards and reduces the time needed for certain processes through rapid temperature changes. - Temperature range with humidity from -42 to +190°C. - Temperature range without humidity from +10 to +95°C. - Humidity range from 10 to 98% rh.

|

|

| Technical Data |

|

| Genaral Specifications |

| Working temperature range | +7 above ambient temperature up to +90 °C |

| Temperature range | without humidity: from -42°C up to +190°C

with humidity from +10°C up to +95°C |

| Temperature distribution(spatial) | +/- 0.5 up to 2K |

| Temperature sensor | 2 Pt100 sensors DIN Class A in 4-wire-circuit for mutual monitoring, taking over functions in case of an error |

| Display | resolution of display for setpoint values 0.1°C up to 99.9°C, 0.5°C from 100°C and for actual values 0.1°C (LED) |

| Controller | Electronic microprocessor temperature controller with auto-diagnostic system |

| Timer | integrated timer for tempering profiles of up to 40 ramps each, each segment adjustable from 1 min. to 999 hrs. |

| Set-up display | digital display of all set parameters, such as temperature, weekdays, time, humidity, fan speed, programme status and set-up values - language to be chosen via set-up |

| Calibration | three freely selectable temperature values, humidity 2-point calibration at 20% and 90 % rh |

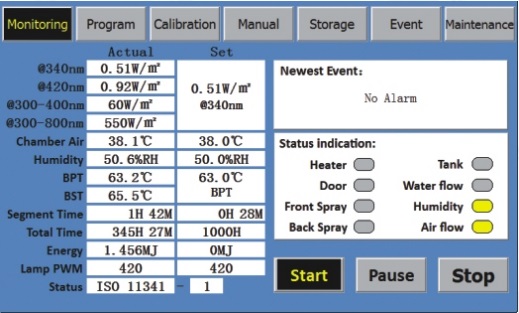

Grandetop GTC800 Climatic Test Chamber Fast change rates testing chamber is suitable for testing the changes of instruments, electrical, electronic products, machine and parts under the rapid temperature change or the gradient conditions, takes advantage of compact, modern scroll compressors to bring fast temperature cycling to small form factor. |

Features

- Temperature cycling rates from 3 to 30°C/min are possible. - Temperature range from -40 to +150°C. - Humidity range from 20 to 98% rh.

|

|

|

|

Buiged BGD860 Xenon Test Chamber

● BGD 860 Powerful, highly cost-effective, easy to use and convenient to maintain xenon test chamber. ● Use an imported air-cooled xenon lamp and relevant daylight filter, to simulate the full spectrum sun light of outdoor, ensure the test results obtained from laboratory have a perfect correlation with outdoor application. ● Ensure each sample can obtain the same and uniform irradiance during the whole test. ● Outer filter of soda lime. ● Irradiance range from 0.5 to 1.35 W/m2 (420nm). ● Black Board Temperature range from +30 to 90°C. ● Humidity range from 20 to 75% rh. |

|  |

Contact us at info@simtrum.com for customized service.