| Introduction Optical and functional coatings are used to enhance the performance of a component in various aspects of properties. For example, and uncoated polymeric lens reflects about 8% of incident light at each surface. To reduce the reflection to less than 1%, anti-reflection dielectric coatings can be applied on the lens surface via Physical Vapor Deposition (PVD). For optical components that transparent in nature but require reflective mirror surfaces, dielectric or metallic coating can also be applied to provide highly reflective surfaces. Other properties such as anti-finger-print, anti-dust, anti-fogging and hard protective layers are also parts of the coating application.

The performance of a coating depends on the number of layers, their thickness, the refractive index difference between them, and the material of each layer such as oxides, metals, or rare earth metals.

|

Product Brochure Link:  Contact us at info@simtrum.com for customized service |

In-House Coating Capabilities ● Hydrophobic / Superhydrophobic / Oleophobic ● Anti-Fogging / Hydrophilic ● Polarization-Dependent Coating (Polarizers, Polarizing Beam-splitter) ● Optical Filter Coating (Dichroic, Long-pass, Short-pass, Bandpass, Notch Filters) ● Protective / Hard Coating ● Highly-Reflective Coating ● Anti-Reflection Coating |

Optical Coating on Lens |

Available Coating Materials ● Metallic Materials: Gold, Silver, Aluminum, Nickel, Chrominum, Copper, Titanium, etc. ● Dielectric Materials: Aluminium Oxide, Silicon Oxide, Titanium Oxide, Tantalum Oxide, ITO, etc. |

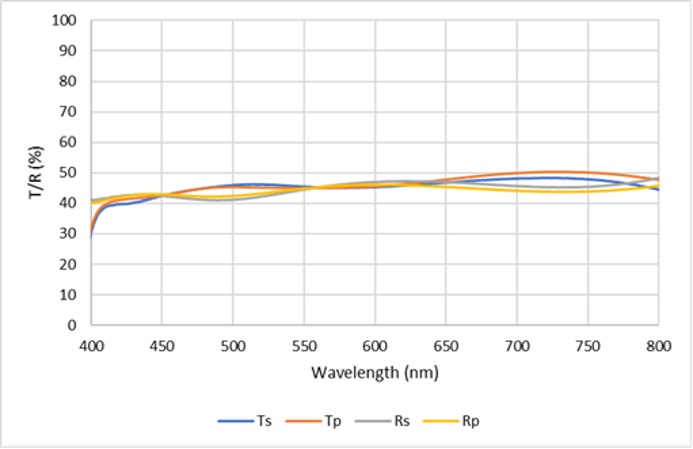

Non-Polarization Beams-plitter Coating (Tavg=Ravg= 45-50% @ 400-700nm) |

Established Coating Technologies ● Leybold Physical Vapour Deposition (PVD) Ø1.0m & Ø1.30m Chambers ● Plasma Assisted Reactive Magnetron Sputterer ● Automated Spray Coater |

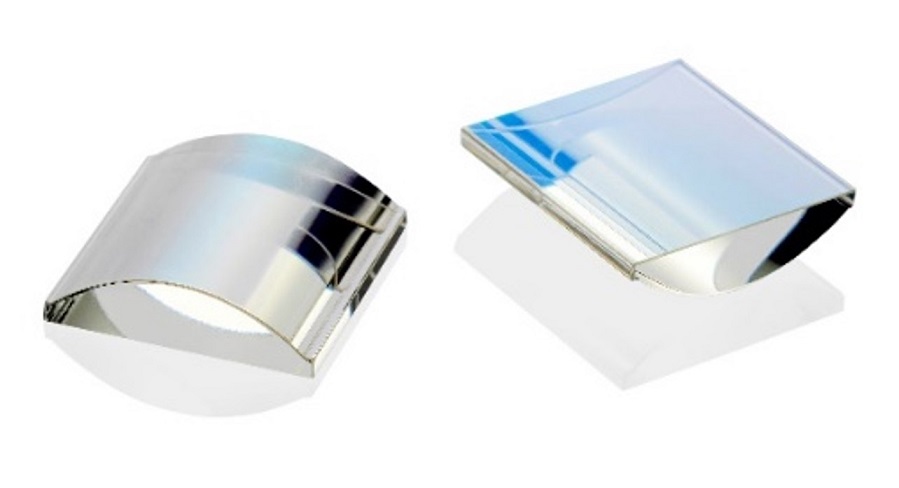

Selectively Reflective Coating on Lens |

| Optical Design & Simulation Software |

|

|

|

|

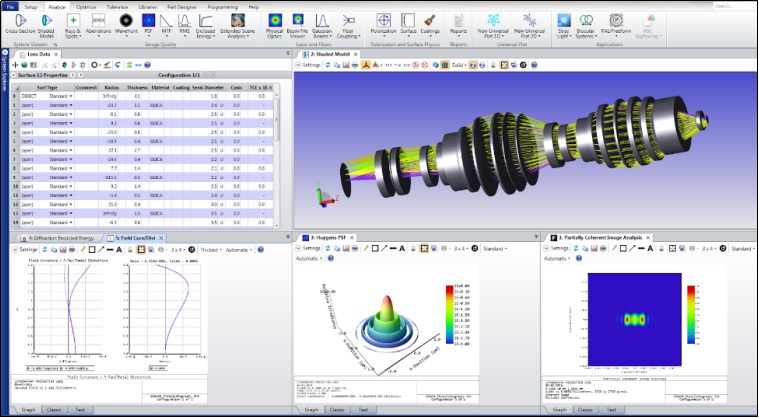

Zemax Optic Studio Refractive imagig & illumination designs & simulations |  |

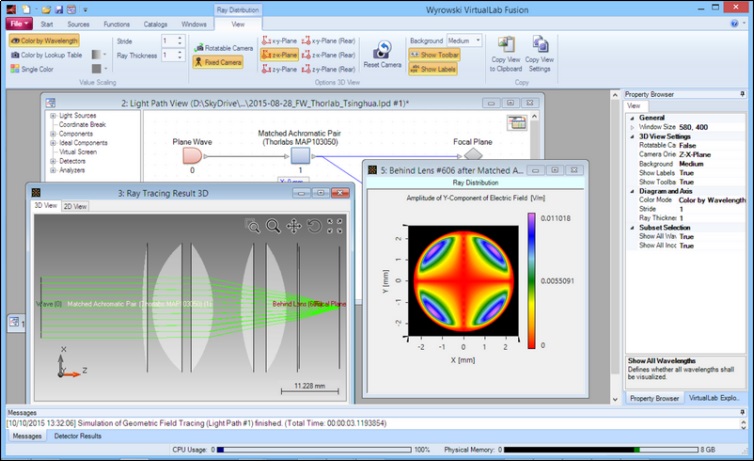

| LightTrans VirtualLab Design & optimization of diffractive beam-splitters, beam-shapers, diffusors and custom image projectors for a single wavelength light sources. |  |

|

|  |

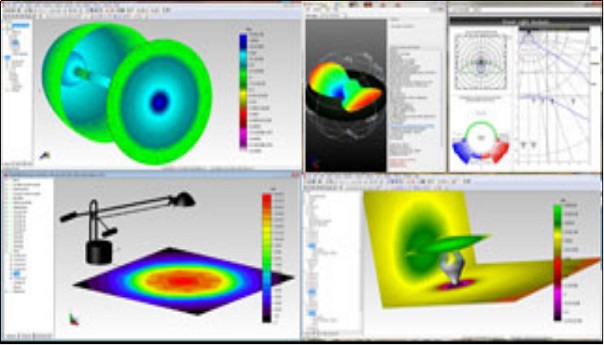

TracePro Design & optimization of diffractive beam-splitters, beam-shapers, diffusors and custom image projectors for a single wavelength light sources.

|  |

|

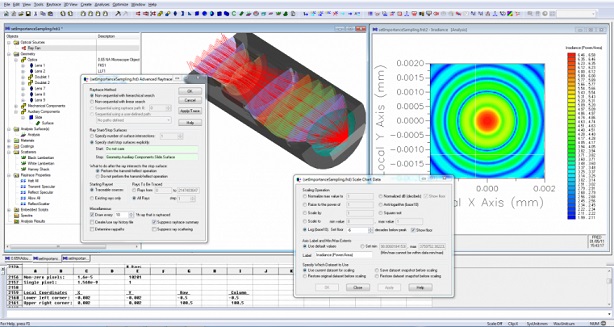

FRED Simulation of the propagation of light through any optomechanical system by raytracing |  |

|

|  |

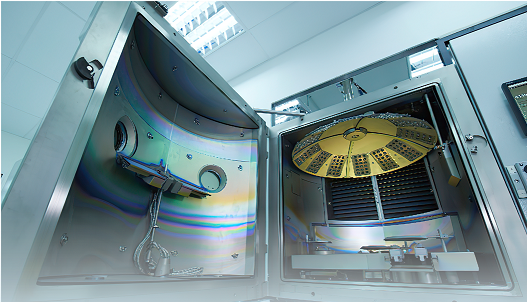

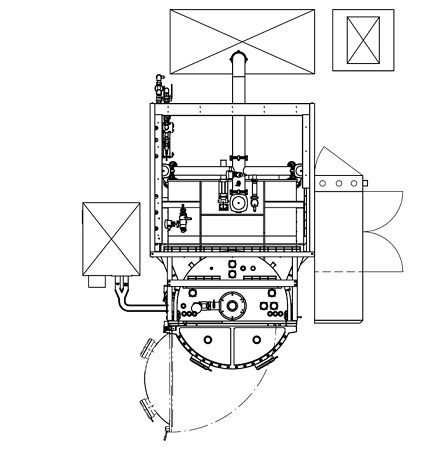

| Our Equipments Bühler – ARES 1100 & 1350

● ARES series is a high vacuum coating system utilizes PVD method to create accurate optical thin films. ● It is capable of achieving optimum levels of productivity by providing maximum through put in its spacious chamber. ● Variety of coating applications include Anti-Reflection, High Reflectance, Anti-stick coatings, bandpass filter and dielectric coatings. ● Customized jigs and fixtures, lateral rotating tools made it possible for coating from all angles.

|

Applications

- AR coatings - Anti-fingerprint coatings - Color filters - Edge filters - Cold-light mirrors - Touch screens |

|  |

Technical Data

|

|

|

| Systems | ARES 1100 | ARES 1350 |

| Coating Materials | All commonly used dielectrics, metals, fluorides, sulfides |

| Coating Technology | Ion-assisted deposition (IAD) /

Plasma-ion-assisted deposition (PIAD) |

| Chamber Diameter [mm] | 1100 | 1350 |

| Chamber Diameter [inch] | 44 | 53 |

| Loading Capacity Ø 65 mm |

| Calotte [pcs.] | 186 | 277 |

| Segmented Dome [pcs.] | 4 x 42 | 4 x 63 |

| Planetary System [pcs.] | 73 | 79 |

CYSI - Three Targets DC Magnetron Sputtering Coater

● CY-MSP300S-3D is a sputtering machine employs energy bombardment to create a single or multilayer film. It deposits very high purity of coatings onto essentially any substrate. ● Ferroelectric thin films, conductive films, alloy films, dielectric films, optical films are possible with this machine. ● Sputtering target up to 3mm for non-magnetic target; up to 1.5mm for magnetic target. ● Substrates size up to Ø185mm. |

|

| Technical Data |

|

| Parameters | Specification |

| Ultimate Vacuum | 5x10-4Pa |

| Sample Table Parameters |

| Size | φ150mm |

| Heat Temp | 500℃ max. |

| Temp Control | ±1℃ |

| Rotation Speed | 1-20rpm adjustable |

| Magnetron Sputtering Head Parameters |

| Quantity | Size:2 inches x3 |

| Cooling Mode | Water cooled, flow 10L/min required |

| Water Chiller | 10L/min Circulating water cooling |

Quartz Vibrating Film Thickness Gauge | One set, resolution 0.10 angstrom |

Contact us at info@simtrum.com for customized service.